Possible Engineering and Automation. Founded in 2020. Our manufacturing facility is located at historic city of Pune, in Maharashtra State of India.

Gat No. 97/13, Flat No. 9, Nevruti Heights, Moshi Pune - 412105, Maharashtra, India

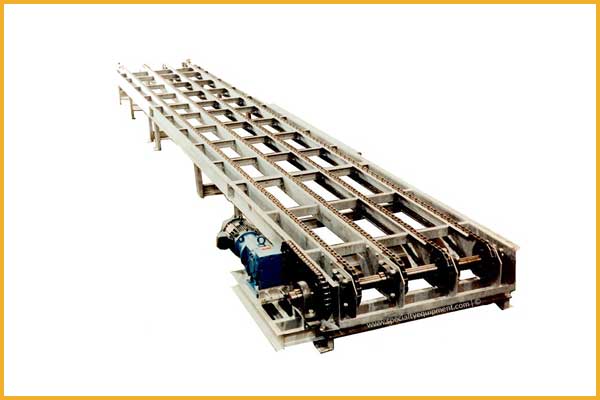

Possible Engineering and Automation is a leading chain conveyor manufacturers in Pune, suppliers, and dealers in Pune, offering high-quality chain conveyors. Our chain conveyors incorporate the latest technology, including automatic loading and unloading features, designed to enhance productivity and streamline operations. Engineered for durability and strength, our chain conveyors are ideal for heavy-duty applications across various industries.

With over 10 years of experience in manufacturing and automation solutions for industries such as automotive, food processing, packaging, and pharmaceuticals, Possible Engineering and Automation understand that every business has unique requirements. Our team works closely with clients to design and manufacture custom chain conveyor systems tailored to specific operational needs, ensuring maximum efficiency. As leading chain conveyor manufacturers in Pune, we provide high-quality chain conveyors to a wide range of industries.

Chain conveyors are a type of mechanical transport system widely used in industrial settings to move materials efficiently. These conveyors rely on a continuous chain, typically made from metal links or slats, which moves products or materials along a fixed path. Powered by a motor, the chain drives movement in a specific direction, enabling the transport of items across various sections of a production line, warehouse, or manufacturing facility.

With over 10 years of experience in automation solutions, we specialize in designing and manufacturing custom chain conveyors for seamless integration into various industries, including automotive, food processing, and packaging.

We are the reliable Chain Conveyor Manufacturers in Pune.

Our chain conveyors are used across a variety of industries:

Below are the details of our various chain conveyor types:

| Conveyor Type | Description | Applications |

|---|---|---|

| Roller Chain Conveyor | Utilizes a chain with rollers to reduce friction and efficiently move heavy products over long distances. Suitable for continuous industrial operations. |

- Heavy Equipment Manufacturing: Moving machinery parts across production lines - Automotive Production Lines: Conveying assemblies and parts - Material Handling: Transferring large materials in warehouses and factories |

| Pallet Chain Conveyor | Designed for transporting loaded pallets using a durable chain mechanism. Common in automation and logistics environments. |

- Palletized Goods Handling: Efficient transport in warehousing - Distribution Centers: For pallet storage, sorting, or dispatch - Warehouse Systems: Supports automated inventory operations |

| OverheadChain Conveyor | Suspended system that transports items via hooks or carriers above floor level. Ideal for space optimization and multi-level workflows. |

- Automotive Production Lines: Moving car bodies and components - Paint Booths: Transferring parts through painting processes - Assembly Operations: Connecting different workstations |

| Drag Chain Conveyor | Uses chains with paddles/flights to drag bulk material through an enclosed casing. Best suited for powders, granules, and similar materials. |

- Grain Handling: For transporting grains in agriculture and food industries - Ash Handling: Common in power plants - Bulk Materials: Used in chemical and processing industries |

As one of the leading chain conveyor manufacturers, suppliers, and dealers in Pune, Possible Engineering and Automation is committed to revolutionizing material handling through modern, tech-driven conveyor systems.

All our conveyors come with integrated PLC programming to ensure smooth, real-time, and error-free operations. Contact us today to transform your industrial workflow with advanced chain conveyors in Pune!

Tags: Chain Conveyor Manufacturers in Pune, Chain Conveyor Suppliers in Pune, Chain Conveyor Dealers in Pune, Chain Conveyors in Pune